DST has to work very hard in order to keep a good PVA sponge quality position among the manufacturer. Among all the action, continual improvement is the momentum driving us moving toward a new era of the cleaning process.

Even though we are facing severe resources restriction but this is not the reason for us not to improve. Currently, the entire world is facing COVID pandemic challenge, this has given us the best opportunity to look inward to find the opportunity to improve a better sponge quality.

We have outlined several actions for improving a better quality PVA sponge.

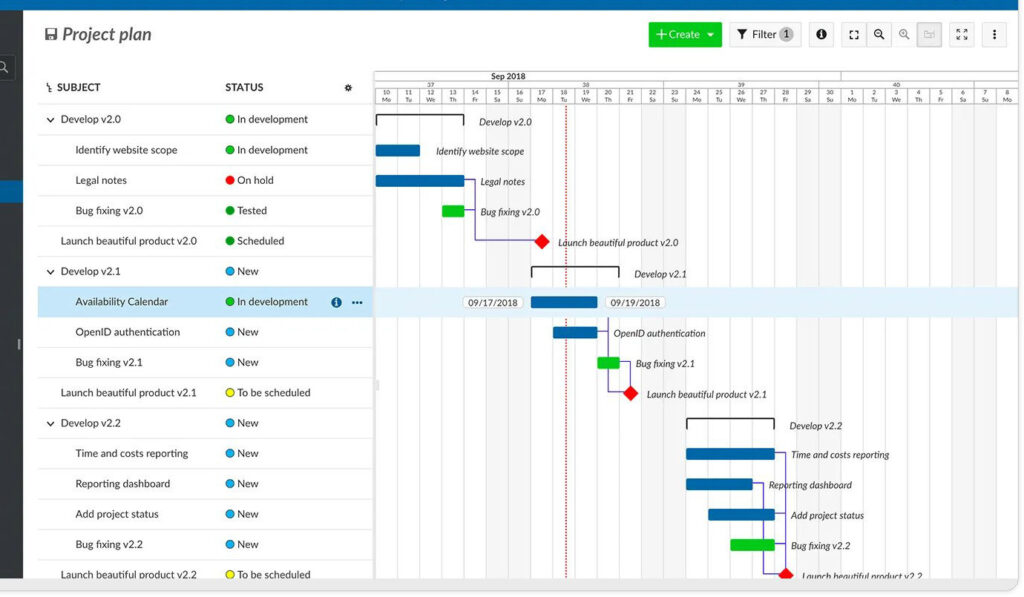

Business Activity, Digitization

We have re-visited the entire business process, start from order receiving, production planning, site manufacturing, quality check packing and delivering. Besides those site manufacturing process, most of the supporting process has been digitized.

In order to reform ourselves for better position in the year 2021, we have outlined several achievement target for improvement.

Business & Management Process

With some standardization effort and management software upgrading, by Q1 2021, we will convert 85% of the work to allow Work From Home mode.

Sponge Manufacturing

Due to overall worker constraint as well as providing wider workspace to minimize the virus spread, most of our workers are carrying out shift duty. Furthermore, our manufacturing worker has been re-trained for multi-work ability. So that we could carry out our sponge manufacturing process even with 50% of site attendant.

New Product Development

We supply the PVA sponge to many local factories. However, there are many other sectors which we want to cover. Among the possibility, we have identified 2 main products to explore a better market position in the year 2021 and onward.

- PVA Foam Wiper

- PVA Sponge Block

Process Improvement, Standardization

DST has supplied PVA sponge roller for various manufacturing industries for pass 10 years. Meanwhile, we have developed a different process control parameter in order to achieve better product for an individual process.

Start from Q4-20, we already kick-started a standardization sponge manufacturing process whereby we want to streamline the manufacturing process parameters. This is the standardization process so that abundance of raw material could be minimized.

With the manufacturing standardization, this will ensure the manufacturing process could operate in better efficiency. However, we still carry out engineering work, but this part is solely left for engineering stuff.

PVA Sponge Process Improvement

Sponge cleanliness becomes more demanding in the process. We have to improve our sponge cleanliness in order to have the flexibility to use in various industries.

We have discussed PVA sponge cleanliness in a separate article. Meanwhile, we also improve the cleanliness testing capability so that we have tools to examine the sponge cleanliness.

We also upgraded our cleaning process so that we could achieve better sponge quality. Perhaps, with the cleaning tools, we could set up our process becomes more reliable and stable.

We know every industry is facing various challenges, we have to turn our mindset whereby we could take this as the moment to drive for improvement. We are grateful to have our customer support and bare with us for PVA sponge improvement.

One Response