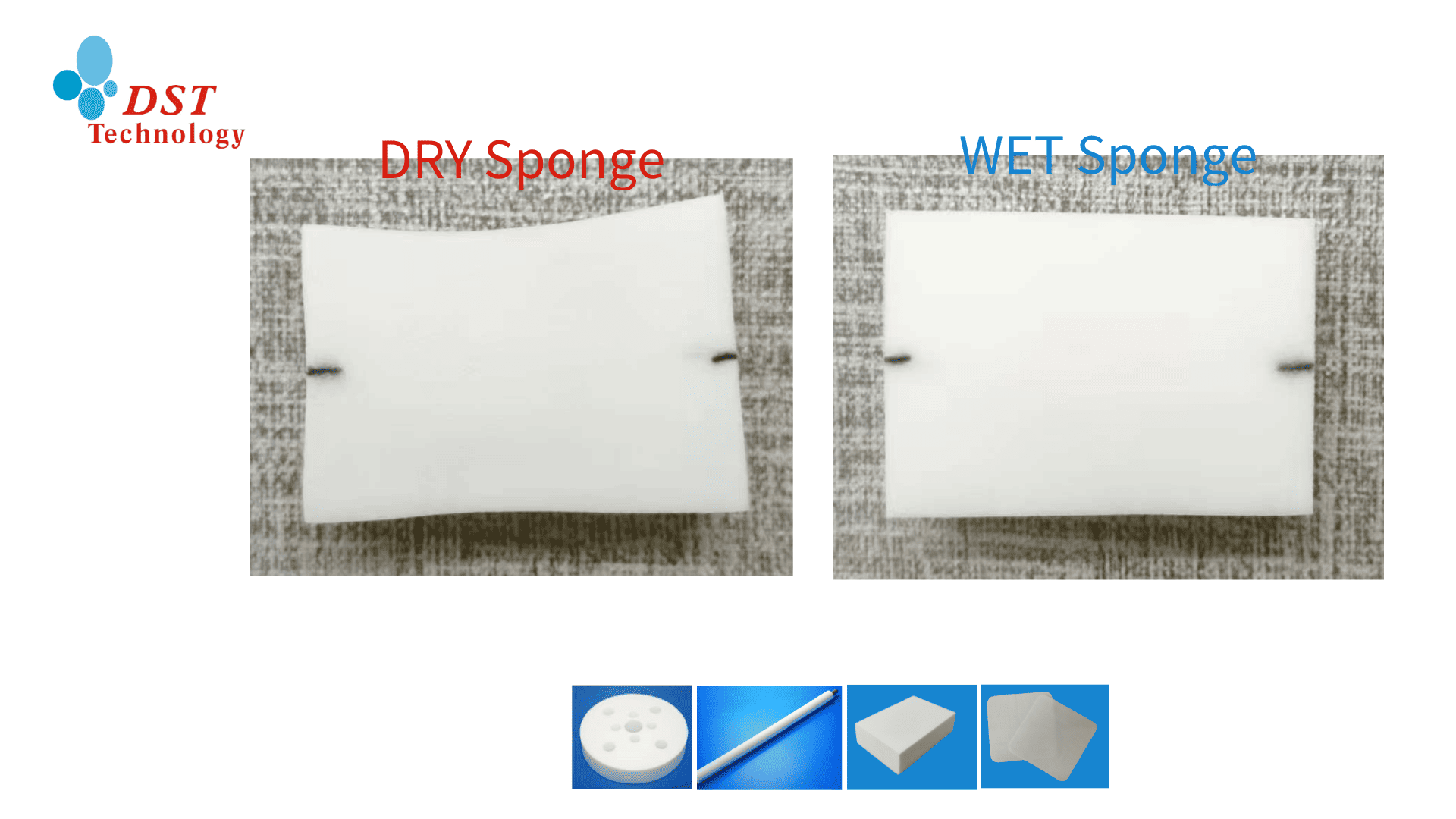

PVA sponge does shrink as moisture evaporates. Unlike EPDM or PU sponges, PVA shows more noticeable dimensional shrinkage when it dries completely — a characteristic intrinsic to its material structure.

This shrinkage often causes confusion for cleaning field engineers. Since PVA sponges are intended to be used in their wet state, we typically reference wet-stage dimensions when discussing measurements with customers. Because shrinkage is unavoidable, we confirm dimensions clearly with new customers to prevent misunderstandings.

PVA Sponge does shrink along with the moisture evaporate.

How much Dimension Shrink?

PVA sponge is known for its excellent water absorption — in some cases holding up to 10 times its weight in water. Rather than simply evaporating like free water on a surface, water trapped inside the sponge behaves differently.

Here’s why moisture evaporates more slowly from PVA sponge:

- Water resides in microscopic pores throughout the material.

- Capillary forces hold the water tightly inside the structure.

- The porous matrix limits exposure to air.

- Lower airflow and smaller temperature differences further slow evaporation.

Because moisture is held deep within the sponge, dimensional shrinkage isn’t just about how much water is lost — it’s also how the structure adjusts as that water leaves.

How Fast is the Dimension Shrink

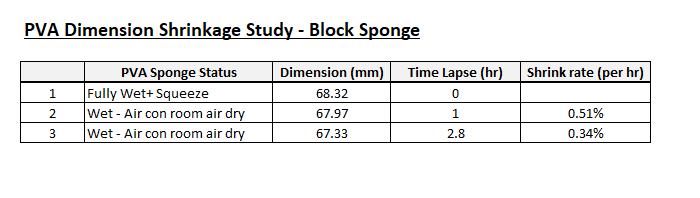

At DST, we conducted tests on PVA sponge blocks to observe shrinkage behavior over time.

According to our recorded data:

- First hour: Shrinkage happens most quickly, at about 0.5% per hour.

- Subsequent hours: Shrink rate slows to roughly 0.3% per hour.

These rates are influenced by environmental conditions. Under hot, dry weather, the sponge may shrink faster than under cooler, more humid conditions.

Sponge Surface Morphology Change

Beyond reduced dimensions, surface dehydration also affects the sponge’s texture. A dry surface tends to feel firmer, which can unintentionally scratch the substrate during cleaning if the sponge isn’t properly wetted before use.

Why Shrink Matter?

Understanding shrinkage helps field engineers make better decisions when installing and using PVA sponges. For example:

- A 140 mm sponge roller might quickly shrink to 138 mm or less if it dries before installation.

- If the sponge dries during machine downtime, surface dehydration can shorten its lifespan, reduce cleaning efficiency, and potentially damage surfaces.

To avoid these issues, we recommend:

✔ Soaking the sponge thoroughly before installation.

✔ Re-wetting it immediately after machine shutdown or idle periods.

✔ If removal isn’t feasible, rehydrate the sponge at regular intervals.

Pay attention to dehydration — it affects both performance and service life.

At DST, we supply a range of PVA sponges for industrial and commercial applications. Please contact us if you want to learn more about these versatile cleaning tools.

No responses yet