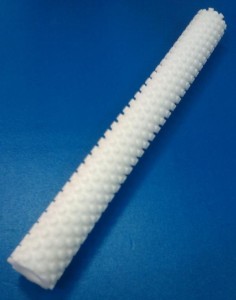

DST has consistently supply high quality and consistent PVA sponge roller product for semiconductor, electronic and PCB process. Many customers always curious about our knowledge and commitment toward cleaning process, the main reason is, we are proud of our PVA sponge roller.

Knowledge on PVA Sponge

DST has focus in cleaning industry for 5 years. We have a dedicate R&D team in order to cope with the latest development growth on sponge roller as well as customer needs.

Due to critical of cleaning requirement, DST has worked with customer develop new micro structure of PVA sponge for improving the cleaning result. We have developed various micro structure sponges such as difference pore size, sponge harness or stiffness for customer needs.

Consistent PVA Sponge Roller Process

Our PVA sponge has gone through a stringent control process before deliver to customer site. The details through-out the process is well taking care off.

We setup certain control to ensure our manufacture quality sponge:

1) Process design. We are able to develop a reliable foaming mechanism.

2) Process control. We setup a monitoring scheme for individual foaming process, this is to ensure every sponge manufacturing process is manufacture under a control environment.

3) Product buyoff. Our final products will be examined for compliance by sampling check.

Focus in details on Sponge Roller Manufacturing

We study the process details as the importance move to show differentiation us from other. We focus in all details in order to minimize the variation by the processes, here are some of our basic setup:

1) Cleaning water quality. During PVA sponge roller manufacturing process, it takes up a substantial amount of water for cleaning. The water quality is directly affecting the sponge roller cleanliness. During our process, we use DI water to clean our sponge roller. Furthermore, the sponge roller will be tested to ensure the ionic contamination is complying to standard.

2) Drying setup. In order to maintain a consistent drying process for PVA sponge roller, we have dedicated drying oven which could ensure evenness of drying. This is also the reason why our PVA sponge roller can maintain better in surface morphology as compare to other sponge roller manufacturer.

3) Mold quality. The mold material and manufacturing process is well established to ensure the sponge quality.

4) Foaming temperature. Foaming temperature is directly affecting the sponge quality. We have documented the foaming temperature for process monitoring purpose.

There are many other parameters for manufacture a quality PVA sponge roller. Making and supplying quality sponge roller is our goal and commitment show to customers.

In DST, we are not only proud for our product but also our technical support in cleaning process improvement. Please call us so we could discuss more on cleaning process improvement.

No responses yet