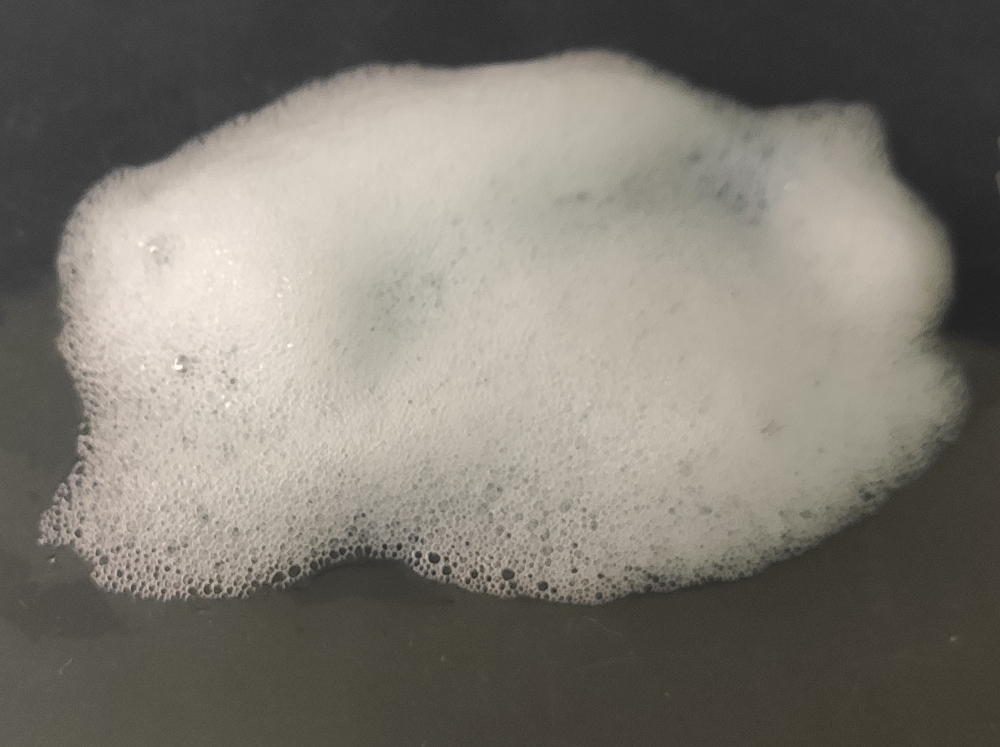

The cleaning field engineering has to work on proper detergent management to avoid the bubble interrupt the process. We know bubble creation and role in detergent. How we are going to manage the bubble foam in the detergent? In general, we are very hard to adjust the detergent formulation due to the bubble amount. Moreover, adjust the bubble amount could be very challenging as this definitely going to affect the detergent performance of the solution and eventually affecting the cleaning result.

In a practical situation, the user always looks for ways and methods to manage the bubble generated during the cleaning process.

Factors Create Bubble

Introducing air into the detergent solution is the key for bubble generates mechanism. In order to manage the bubble condition in the cleaning process, we have to further understand the factors affecting creating bubble amount.

There are several working conditions on affecting the foam or bubble amount in practical cleaning process.

- Impact force.

- Trap air surface

After understanding the factors, cleaning process engineer should have better idea how to setup the cleaning process so that the bubble amount becomes manageable for their process.

Impact Force Reduction

In ordinary cleaning process setup, the detergent solution will be spray on the clean substance, the solution will further drop to the reservoir at the underneath before it being drained out. In this case, the distance for detergent free fall on to the reservoir surface is direct proportion to the impact force.

Reducing the free fall distance should be the first objective in minimize bubble creates in the process.

Material Selection in touch with Detergent Solution

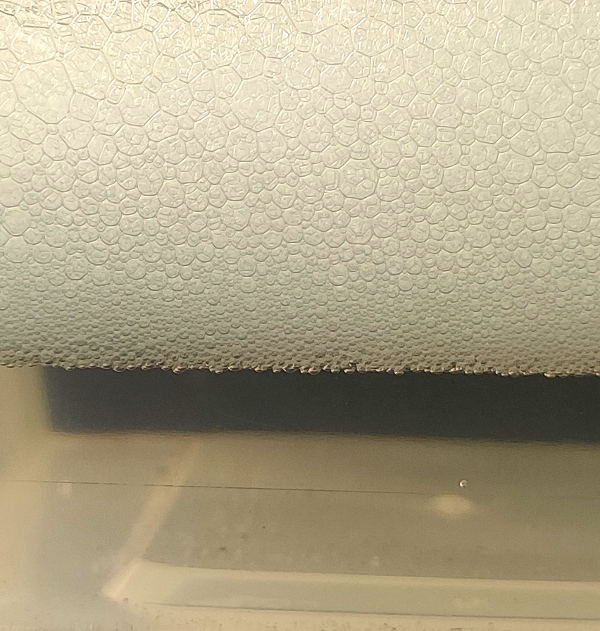

Difference damping material will generate difference bubble amount even under same working condition. Through our experiments, we found out that a solid material will create less bubble then substance with a lot of pore or air trap.

We have tested a few materials:

- Solid plastic plate

- Sponge block

- Scouring pad

Among these 3 damper materials, we found out solid plastic plate create less bubble than the other 2 damper substance.

Drain the Bubble on the Detergent Solution

While bubble being accumulate in the reservoir, now we have to find way to remove, perhaps it is not easy. Bubble is floating on the upper portion in the reservoir, and the draining discharge always locates at underneath of the reservoir. This means only the detergent solution being drained out but left the bubble on top.

If the bubble left on the reservoir, we have to wait some time wait until the bubble burst naturally. Process owner could apply some defoamer on the bubble to make it burst efficiently. However process owner should be very caution whether the defoamer could cause cross contamination to the cleaning process.

Since defoaming could be challenging to the cleaning process, process owner has to find a way to reduce the bubble generation.

- Reduce the impact force from detergent against the bubble.

- Immediately drain out the detergent solution before the bubble grows.

We are confident the bubble creates by the detergent could become manageable with proper detergent flow setup, this needs the contribution from the cleaning process owner.

DST has worked with our customer on overcoming cleaning process challenges. This is an example how we contribute our knowledge in detergent bubble management. With the knowledge apply, we do not require perform modification in detergent formulation. Please contact DST for your cleaning process needs and we are confident there always a way to get a better cleaning process.

One Response