NS Defoamer is a silicone free defoamer specially formulated to fulfill industrial requirement. This dedicated non-silicone based defoamer gives semiconductor industry in Malaysia another alternative for defoamer selection. Many cleaning field engineers have struggle for silicone free defoamer until the NS Defoamer marketed.

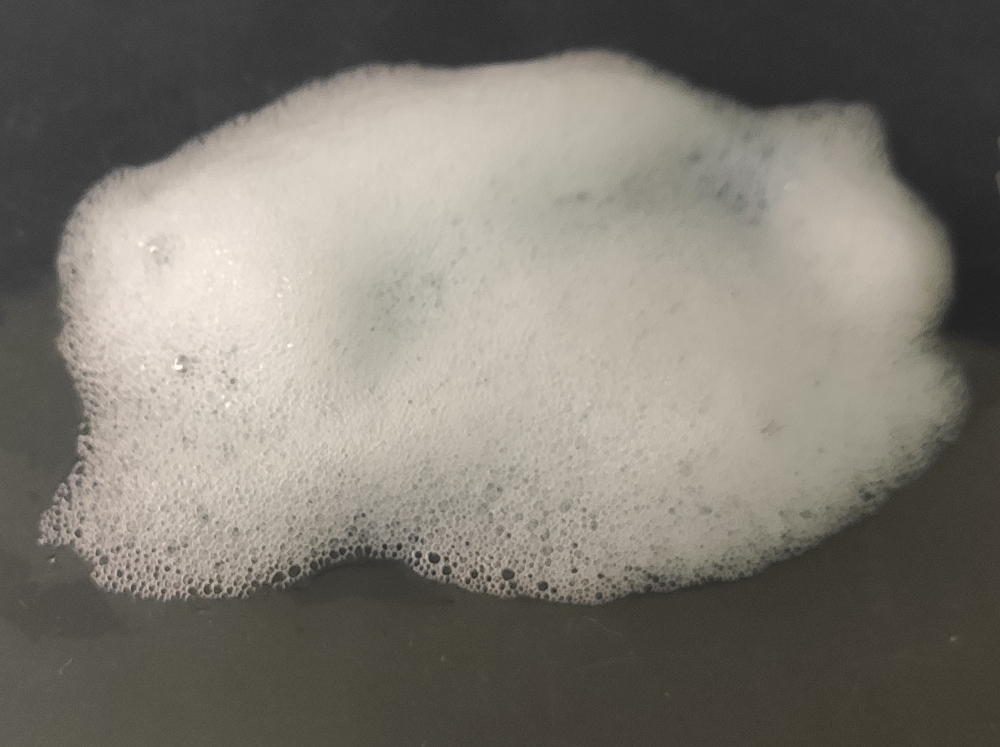

The beauty of NS Defoamer is that the formulation has removed the common silicone compound. Even without the composition of silicone glycol, the NS Defoamer formulation still be able to burst the foam and release the trapped air.

NS Defoamer is your choices if you are looking for silicone free defoamer.

General Features about NS Defoamer

The NS Defoamer is a silicone free and neutral based formulation. It comes in the concentrated solution whereby user could dilute with water under 300-500 ratio. Hence, it provides a better flexibility for user to fine tune the dilution ratio base on their application need.

User could directly spray the diluted NS Defoamer toward the foam area or install an auto dispenser sprinkler with a diaphragm pump. Since the NS Defoamer comes in neutral pH, hence it works fine with all the pumping system and container.

In general, below are a few main features for NS Defoamer

- A Silicone Free Formulation dedicate for industrial application.

- Neutral pH.

- Dilute with water with the ratio of 300-500.

- Comes with pleasant smell.

Application of NS Defoamer

Since NS Defoamer comes in high concentrated format, hence user is required to dilute the defoamer before application. However, the dilution is pretty straight forward. By adding sufficient amount of water into the defoamer after that follow with moderate stir for the defoamer solution evenly disperse in the solution.

Below are the major steps for application:

- Dilution. Add water into the NS Defoamer, we recommend 300-500 mixing ratio.

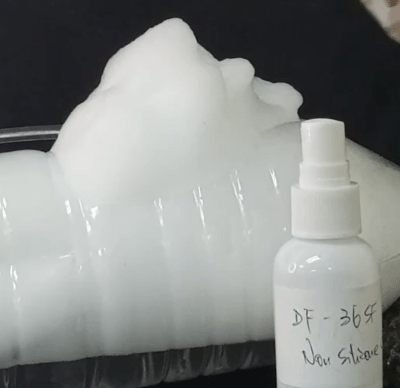

- Stir. With moderate stir the solution, let the defoamer evenly disperse within the solution. The solution shall change to milky white colour.

- Bottling. Put the diluted defoamer into the bottle or dedicate storage tank.

- Spray. Directly spray the diluted defoamer against the foam.

Even though the concentrated defoamer may cause slightly inconvenient for user who want sporadic defoaming effect. But this will gives the maximum advantages for industrial process consistent spray application.

Packaging

The NS Defoamer comes in 500ml and 10L packaging method. The 500ml bottle suitable for user who apply manually. Whereby, the 10L pail is more suitable for industry application. However, we could adopt other packing size based on customer needs.

- 500ml Bottle. Mix up to 150L working solution. Suitable for manual application.

- 10L Pail. Mix up to 3,000L working solution. Suitable for industrial application.

User could select silicone free product in order to improve from cleaning process cross contamination.

DST has further strengthen our product line with this Silicone free defoamer, NS Defoamer. Hence, this non silicone based defoamer gives the cleaning field engineer a better position to minimize cross contamination.

Contact DST in case you want to understand more about our silicone free defoamer.