Similar to many plastic material, the PVA sponge has shown good chemical resistance performance for most of the chemical. The good chemical resistance is referring to the sponge roller does not has significant impact in product life span.

Unfortunately, there are several chemical or acid solution are actually deteriorating the PVA sponge quality, for instance the sulfuric acid. PVA sponge material could withstand low or diluted sulfuric acid, but a concentrated sulfuric acid will deteriorate the sponge quality as short as 10min.

PVA sponge mostly resistance to many chemical solution.

Why Bother about Chemical Resistance?

In many wet process, the field engineer may use various of detergent or chemical in order to achieve certain cleaning result. Under this circumstance, the sponge withstand chemical ability becomes a challenge to field engineer.

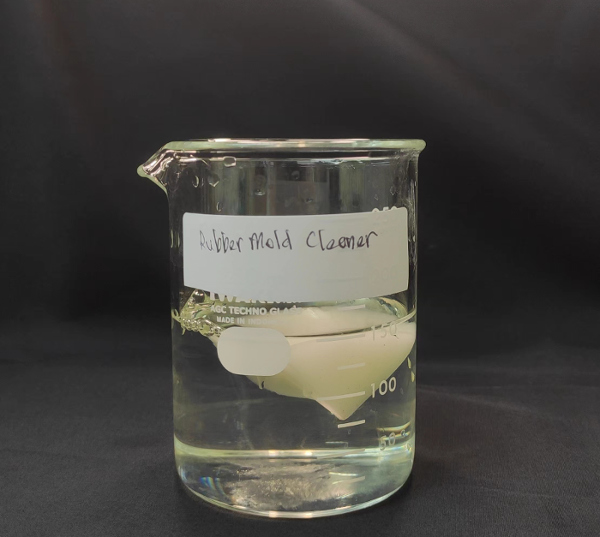

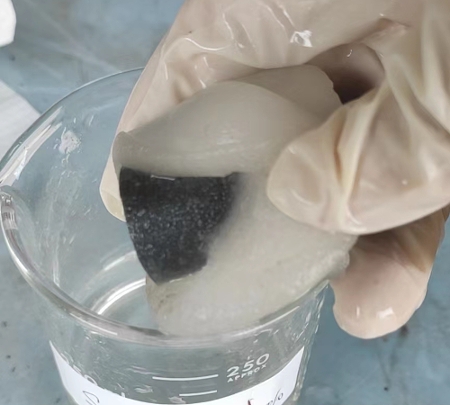

Some of the cleaning chemical, it contains with solvent ingredient. This is because solvent is suitable for removing wide range of contaminants. For the detergent consists of solvent solution, the field engineer has to be extra cautious in sponge selection. For instance, he shall examine the sponge material by soaking the sponge into the chemical solution in order to examine the compatibility.

For the sponge which incompatible with the chemical solution, the sponge may degrade faster. The PVA sponge degradation may refer to:

- Sponge properties change.

- Sponge discolouration.

Chemical Solution that Damage the PVA Sponge

In general, PVA sponge consider a good chemical resistance sponge. However there are some chemical solution which will damage the sponge, for instance

- Alcohol Solution

- Bleach

- HOCl

- Sulfuric Acid

Besides the above, there are some other chemical solution which may accelerate the sponge aging process, such as

- Thinner solution

- Spirit solution

Extend PVA Sponge Roller Life Span

For those less harmful solution, we always recommend the user to clean the sponge with plain water in order to extend the sponge life span. Perhaps, in many processes, the field engineer will perform sponge cleaning not only extend the sponge roller life span but also maintain the sponge cleanliness. Most of the sponge cleaning is carrying out via manual cleaning. Whereby we are also designing sponge cleaning facility for our customer who wants a proper cleaning facility.

Other Sponge Materials

In case your process will involve the above chemical solution, then user could consider to choose dedicate sponge roller, such as PU, PVC or PO sponge roller. Those dedicate sponge materials consider special material which always the less choice for the process.

Feel free talk with us for chemical resistance on sponge roller. We shall find a way for you to improve the process with an appropriate sponge material selection.