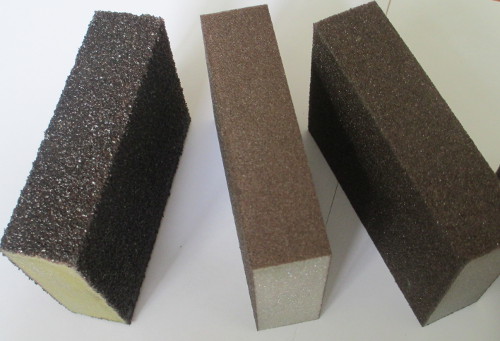

Lately, we come across an abrasive sponge block in a hardware shop, the product is so similar to our PVA sponge block. In quick glance, the product looks familiar to us, just bond a layer of abrasive oxide on the outer layer of the square PVA sponge.

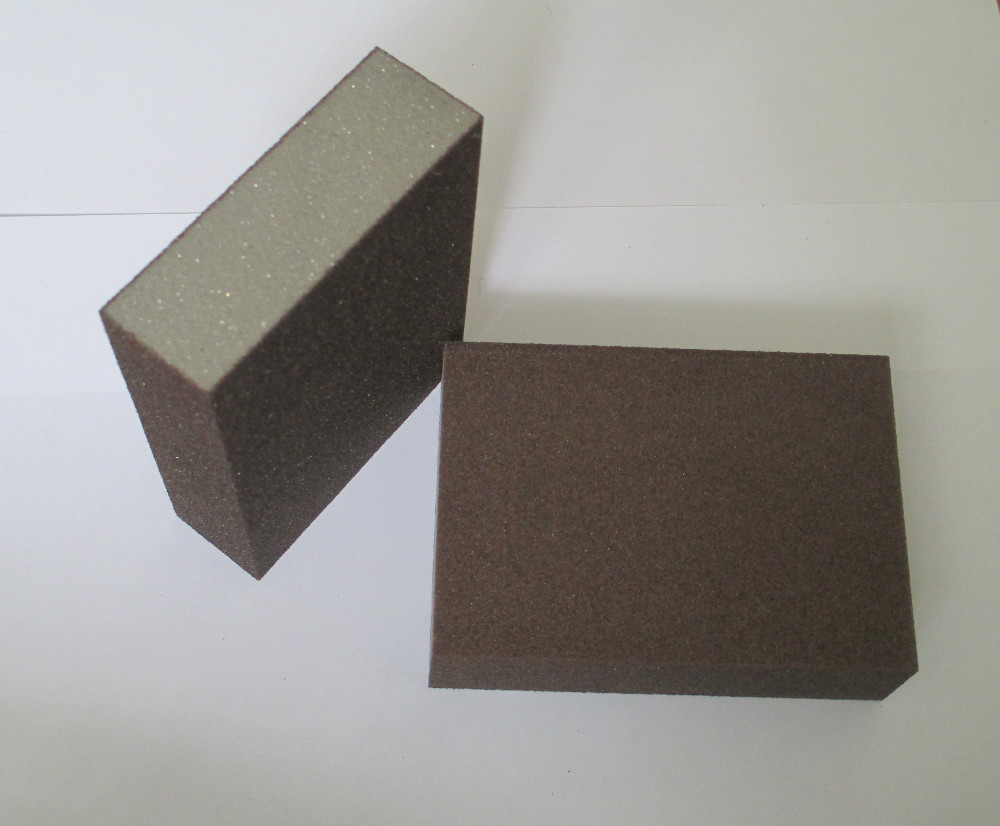

This is a kind of abrasive sanding sponge which is able to work at the wet condition. Perhaps, the ability to work at wet stage conditions gives a better alternative to surface finishing.

An Abrasive Sponge Block able to polish the surface with cleaning detergent or polishing solution. This gives a better metal-working finishing surface.

The Abrasive Sponge Block Material

Sponge Materials

There are two ingredients in an abrasive sponge block:

- Foam.

After close examination, the foam is for the sanding sponge is a PU Sponge but not a PVA sponge. Perhaps, the PU sponge coated with the abrasive will give additional removing capability. And the mm size porous structure also causes less clog up from the removal metal. - Abrasive.

The abrasive is the aluminum oxide powder which segregates into different mesh sizes. Select the abrasive size base on the fine to coarse surface requirement.

The Bonding

The cement glue is coated on the foam surface prior to the abrasive coated. A good bonding will ensure the abrasive tightly stick on the foam surface.

The Application

The abrasive sponge block is almost an all-purpose sanding foam. Users could use the block sponge under dry or wet polishing conditions. Meanwhile, this product could be used to polish many substance surfaces, this includes:

- Wood Surface

- Metal Surface

- Paint Surface

- Plastic Surface

Users could also rinse clean the sanding sponge after the polishing job completed. Hence, the abrasive sponge is suitable for reusable after cleaning.

Use PVA Sponge Block as the Base Material?

Even though we had compare both the PVA and PU sponge block, and both materials look similar. Many have asked us about the possibility of using a PVA sponge as the base material for the abrasive sponge.

Definitely, we could adopt a PVA sponge in this case. Perhaps, we had seen several lapping stone manufacturers had used PVA resin in the stone manufacturing process. But for the sanding sponge, adopt a PVA sponge may not be a good idea, because of the below reasons.

- Porous size is smaller. May lead to polish slug clog-up.

- Lifted the product cost. The PVA sponge material is much expensive as compared with the PU sponge. By comparing the raw material cost, PVA material is 10 times higher in material cost compared to PU.

The abrasive sponge block is one of the products derived from industrial material. Even though the selling price of this sanding sponge is higher than the traditional paper-based sandpaper, but it gives a good alternative to the user. So, keep an open mind and we believe there will be much more products that come from the industrial material. More important, we are seeing more combination effort by using two different products, which are the PU sponge and abrasive grit.