In the printing industry, the printing plate has to wash and dry with the PVA sponge roller to ensure the plate’s cleanliness. The aged printing plate will have some ink stain mark build-up after a certain cycle of printing. The contaminated plate shall send for plate cleaning.

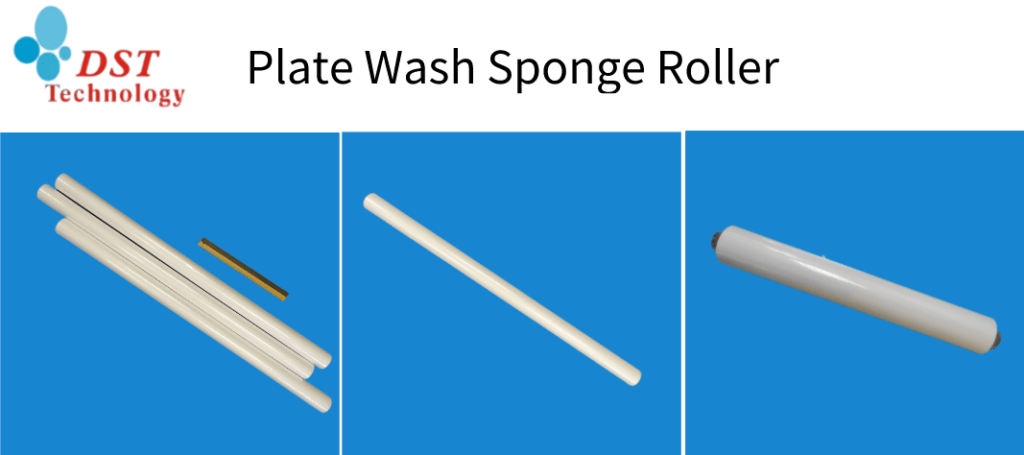

There are many types of roller in a plate wash machine, user may get confused about which is the sponge roller.

Where the Sponge Roller Locates?

Even though there are several rollers in a printing machine, but most of the roller is metal and hard feel roller. Whereby the plate wash sponge roller comes in soft form. In industrial applications, the sponge roller always comes in white colour, but the colorant on the printing plate will easily dye the sponge roller after several circles of cleaning. But it does not significant affect the cleaning performance.

As we observe, in most cases, the sponge roller commonly dyes and becomes a “blue” colour roller in the printing plate wash machine. However, the field engineer will easily identify the sponge roller by visual or hand feel.

Furthermore, the PVA sponge roller always located after the wet cleaning process, this is because the sponge is used to remove the water droplet. The printing plate will easily air dry and also no watermark left on the surface. This is the reason why every plate wash machine always installed a PVA sponge roller in the final cleaning station.

Clean the Plate Wash Sponge Roller

The sponge roller has to take out for cleaning after certain uses. In most cases, we recommend the user takes out the sponge roller and clean it at separate area. But in case you have other constrain, you could also perform the cleaning in the cleaning line.

Clean Roller Offline

For the printing sponge roller, the diameter normally within 80mm, it is pretty easy to remove from the machine. Place the contaminated plate sponge roller in the cleaning zone, free flow the clean water, and manually squeezed the sponge roller to remove the contaminant.

Continue the squeeze process for 3-5min, you are able to clean up the sponge roller effectively. Install the washed roller back in the plate washing machine after the cleaning.

Due to the sponge is contaminated with various colourant, you are advised to wear gloves and necessity PPE for basic protection. Check with the PPE supplier to understand the appropriate guidance.

Clean Roller on the Machine

For a large roller, such as a diameter of 150mm, taking out this roller requires a huge effort. You may have to rinse this large plate roller on the machine. Thoroughly rinse the roller for 5 min, meanwhile press the sponge roller to squeeze out the water to ensure maximum water flushing effect.

Since the PVA sponge roller is having an open pore structure characteristic, it is pretty easy to perform roller flushing and rinsing.

Roller Life Span

Although a quality plate wash roller is having a good life span. But the printing process engineer could observe for several conditions to determine if the sponge’s life span lapses.

- The sponge structure. Sponge tear-off indicates the sponge is reaching the life span.

- The plate condition after clean. Observe accessive water droplet after the plate wash roller process.

- The sponge colour. The sponge roller colour becomes dull.

We are supplying our detergent and rollers for the plate wash process in the printing industry. Feel free to check with DST about your roller needs.