Post CMP Cleaning Process

- On Oct, 27, 2012

- DST

- Surface Cleaning

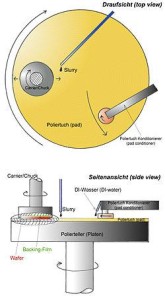

CMP process

Chemical-Mechanical Planarization (CMP) process is the polishing process used in wafer and disc drive industry. Many efforts have been discussed on setting up an appropriate CMP process however not emphasizes being given on post-CMP cleaning process. In order to achieve a better surface appearance, CMP engineer should consider both the polishing process and post-CMP cleaning capability and stability.

Surface requirement is getting tighten for Chemical-Mechanical Planarization (CMP) process, this imply to the post CMP cleaning process as well. Due to the nature of CMP process, slurry, abrasive, pad are introduced, therefore this left Post-CMP cleaning process become more challenging for removing those contaminant.

Contaminant induced during the CMP process

Slurry and metallic contaminantis sitting on the wafer polish substrate surface. The contaminant could come from several sources; here we outline the 3 major contributors.

-

Slurry.

This could be the silicate oxide(SiO2), alumina oxide(Al2O3) or cerium oxide(CeO2), it very much depend on the slurry we select for the CMP polish process.

-

Polish Pad.

This is the polish pad we use during the CMP process. The loose pad material is easy to remove in most cases. By traditional wet surface cleaning process, this contaminant could be removed.

-

Polish surface material.

The metallic contaminant is one of hardest part to remove. It could be securely adhere on the substrate surface or even embedded in the substrate surface.

Criteria for Post CMP Cleaning process

In order to effectively remove the particles adhere on the CMP polish substrate surface, post CMP cleaning engineer should consider from difference aspect.

Change the Surface Property.

Surface tension or wetability plays an important role in wafer substrate cleaning. The difference surface tension or water contact angle will direct impact the cleaning result. Post CMP process cleaning engineer shall determine the wafer surface condition such as hydrophilic or hydrophobic condition. In most case, hydrophilic surface will give better performance in flushing away the contaminant as well as minimize water stain mark. Our EC series detergent does have the ability achieving the surface property to hydrophilic stage.

Slurry use in CMP process.

From all the study and observation, we notice that acidic, neutral or alkaline base slurry gives difference particle adhesion result on wafer surface. In general, alkaline base slurry has lower adhesion force on the wafer surface. In short, the larger the adhesion force, it may cause larger of surface scratch.

Set up the post CMP Cleaning

The direction for setting up a post CMP cleaning process is to obtain a cleaning removal force larger than the adhesion force on the wafer surface. In order to have a cleaner substrate surface, field engineer could either increase the removal force or reduce the adhesion force.

Increase surface removal force.

-

Use soft PVA sponge roller.

Soft PVA sponge roller is the best choice for increasing the removal force. The soft natures of PVA sponge roller will deform while it comes in contact with a particle adhere on the substrate surface. The deformation of localize area will lift up the particle on the surface.

-

Increase medium to high rotation speed.

With high rotation speed, it will proportion increase the removal force.

Decrease particulate adhesion force.

By selecting a proper cleaning detergent, and it additive will help to reduce the particle adhesion force. This is mainly the additive is having a repulsion force to “lift” certain level of the adhesion force. In general case, small amount of ammonia is added in as an additive.

Post CMP cleaning process is a comprehensive science which requires details study and process optimization. The discussion above is just a preliminary understanding for cleaning engineer to consider while setting up the post CMP cleaning process.

Even we have covered some important concept in this article however post CMP cleaning process optimization is needed in order to achieve best surface result.

Leave a Comment