Establish Surface Contamination Inspection and Monitoring

- On Oct, 17, 2012

- DST

- Surface Cleaning

We have discussed several topics about surface cleaning process and contamination in previous articles. In this article, we would like to discuss something about establishing contamination inspection and setup monitoring scheme ensures the surface cleanliness.

Surface contaminant will cause yield impact and reliability to the products such as the process involve surface coating, the surface contamination level will direct impact the coating quality. Field engineer should learn about the visual inspection tools to use for various kind of defects in Setup Surface Inspection for Visual Defect, Particle and Contamination.

Define the Surface Contamination to Monitor

Field engineer shall identify the contaminants or contamination which appears on the product surface. Going through the customer specification or requirement should be a good started for identifying the unacceptable contaminants.

A comprehensive contamination inspection plan should also include the surface inspection tool use through-out the inspection process.

Establish Acceptance Criteria for Individual Surface Contaminant

Field engineer shall tabulate all surface contaminant which identify in previous step and set up acceptance criteria for individual contaminants. A comparison images and illustrate with simple wording about the contaminant will help the process owner to understand the surface contaminant before establish a reliable contamination inspection procedure.

Inspection Plan for Contamination Inspection and Monitoring

Full inspection is always wanted by most people however in a realistic case, we many not be able to perform 100% inspection on the products. In this case, field engineer shall setup an inspection sampling plan comply with certain AQL standard.

Over here, we need to emphasize a concept that establishing contamination inspection plan is not the purpose for ensure product quality. The contamination monitoring plan is for the process owner and field engineer to understand the product quality level.

Moving forward with Contamination Inspection and Monitoring Result

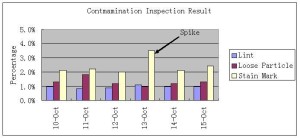

A well establish contamination inspection & monitoring result always be reviewed by the field engineer. The result will reveal by the contamination level of the products and also if any shifting in contaminant particle found. Only with the inspection result, field engineer is able to judge the cleaning process effectiveness and efficiency.

In a precision cleaning process, a more stringent contamination inspection scheme is implemented. Further more, field engineer will setup an trigger limit for individual surface contaminant level. Haven’t said that, while certain contamination level is trigger, process owner shall take immediate action for identifying the root cause and make immediate corrective action preventing the deteriorating of the product quality.

Establish Awareness of Surface Contamination Inspection

Through out our surface cleaning, we are seeing a migration of concern contaminant from time to time. Basic and fundamental training needs to carry out in order to stimulate the awareness on contamination control through out the organization. There are several materials could be used in the awareness training program:

Basic knowledge about Contamination Control

Case study

Reference materials and sample

Achieving better surface contamination level is a never ending process. Only establish an adequate contamination inspection and monitor scheme will help field engineer to identify the root cause of the contaminant and taking effective precautions step for improvement.

DST Technology is your partner for improving surface contamination level. Feel free to contact us for any improvement on surface contamination or establishing contamination inspection and monitoring method.

Leave a Comment